You HAVE to love Spring! Especially when your family is a maple syrup producer. Nothing is more exciting than the sight of blue collection bags, strategically placed throughout a slightly, awakening maple sugar bush. A sugar bush full of maple trees that are coming alive with the sights and sounds of spring. The wildlife is bustling around to find leftover goodies that were preserved by the snow and ice on the forest floor. The birds sing with a bit more happiness as they twitter about creating new nests for their coming broods. And the maple syrup farmer…well, the maple syrup farmer loves all the hustle and bustle of the sugar bush coming to life, but what he really loves is the sights and sounds of raw maple sap, trickling into the farmers choice of collection vessel.

The beautifully clear raw sap begins to release from a mature maple tree when the temperature starts to range in the 30’s at night and rises into the 50’s during the day. The season ends when the trees start to show signs of budding and releasing the sweet green leaves that bless us with shade on a sweltering summer's day. In between this stretch of time is where all the magic takes place.

Over the years I have been asked many questions about maple syrup production while participating as a vendor at farmer’s markets. In this article, I have compiled some of the answers from my personal experiences as a sugar farmer and from talking with other sugar farmers.

Here are some cool facts about Maple Syrup…or….um…sugaring…

1. You Need 40-50 Gallons of Raw Sap to Produce 1 Gallon of Syrup.

Sap collected from the maple tree has an average sugar content of 2-4%, the rest is water. The act of making maple syrup is basically boiling the excess water off the sugar to bring the sap concentrate to a specific gravity. Depending on the equipment, fifty gallons of raw sap can take anywhere from all day to just a few minutes. Our first experience with sugaring was very humble; just a few cinder blocks, two restaurant chafing pans, and some decaying campfire wood. It took better than 10 hours to boil down a 55-gallon barrel of sap to a very dark gallon of syrup. Our current evaporator can boil 55 gallons of raw sap in about 45 minutes and the finished syrup is upscale and beautiful. When it comes to efficiency and the quality of the finished syrup, bells and whistles make a difference.

2. There is a reason that maple syrup producers, their grove of trees, and their shack contain the word sugar and not syrup.

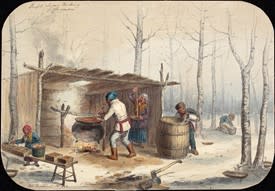

Back in the day, before safe preserving techniques were developed, early settlers and Native Americans would boil down their sap until it was able to be formed into maple sugar. It is believed that the sap was reduced until it was very thick and then poured into wooden molds to produce “cake sugar”. Another technique was to pour the liquid onto the snow to produce “wax sugar” or what we know today as ‘sugar on snow’. These early adopters were referred to as maple sugar makers, the grove of trees was the sugarbush, and the place of production is lovingly referred to as the sugar shack. (photo credit: Ohio State University Extension)

Back in the day, before safe preserving techniques were developed, early settlers and Native Americans would boil down their sap until it was able to be formed into maple sugar. It is believed that the sap was reduced until it was very thick and then poured into wooden molds to produce “cake sugar”. Another technique was to pour the liquid onto the snow to produce “wax sugar” or what we know today as ‘sugar on snow’. These early adopters were referred to as maple sugar makers, the grove of trees was the sugarbush, and the place of production is lovingly referred to as the sugar shack. (photo credit: Ohio State University Extension)

3. Maple syrup has a specific gravity or density, color value, and clarification that must be reached to be considered Grade A Syrup.

To be considered Grade A Maple Syrup, the syrup must be free from any contamination and cloudiness, have a color grade that meets one of four standards, and be reduced to specific gravity. Excellent syrup is reduced to about 67% sugar content or 66.9 Brix. The specific gravity is found by floating a hydrometer in the syrup and reading the values on the device. Another way, but less accurate, is to reduce the syrup to 7-8 degrees above your area's boiling point. For example, if you live at sea level your boiling point will be 211 degrees Fahrenheit which would require the syrup to be taken to 218 to 219 degrees Fahrenheit. All four of these bottles pictured above are grade A in color. The first bottle is Grade A Amber/Delicate Taste and is produced from the first sap run in the early spring. This is the grade sought after for making sugar, cream, and candy. The second bottle is Grade A Amber/Rich Taste, and is derived later in the season and is primarily used for breakfast syrup and has the classic maple flavor that we all love to experience. The third bottle is Grade A Dark/Robust taste and is the grade that usually comes toward the end of the 4-6 week season. This grade has a pronounced maple flavor and is desired by those that crave the stronger flavor and is used mostly for cooking. The last bottle is Grade A Very Dark/Strong Taste and usually only made in exceedingly small amounts and is used in cooking where a strong maple flavor needs to shine through. (photo credit: Hanna Instruments)

To be considered Grade A Maple Syrup, the syrup must be free from any contamination and cloudiness, have a color grade that meets one of four standards, and be reduced to specific gravity. Excellent syrup is reduced to about 67% sugar content or 66.9 Brix. The specific gravity is found by floating a hydrometer in the syrup and reading the values on the device. Another way, but less accurate, is to reduce the syrup to 7-8 degrees above your area's boiling point. For example, if you live at sea level your boiling point will be 211 degrees Fahrenheit which would require the syrup to be taken to 218 to 219 degrees Fahrenheit. All four of these bottles pictured above are grade A in color. The first bottle is Grade A Amber/Delicate Taste and is produced from the first sap run in the early spring. This is the grade sought after for making sugar, cream, and candy. The second bottle is Grade A Amber/Rich Taste, and is derived later in the season and is primarily used for breakfast syrup and has the classic maple flavor that we all love to experience. The third bottle is Grade A Dark/Robust taste and is the grade that usually comes toward the end of the 4-6 week season. This grade has a pronounced maple flavor and is desired by those that crave the stronger flavor and is used mostly for cooking. The last bottle is Grade A Very Dark/Strong Taste and usually only made in exceedingly small amounts and is used in cooking where a strong maple flavor needs to shine through. (photo credit: Hanna Instruments)

4. Maple syrup and maple sugar are a healthier option than store-bought syrups and sugars.

Taking a gander at the ingredient labels on store-bought syrup and comparing it to maple syrup, it is quite clear who the winner is for the "Healthy Choice Award". Maple syrup contains fewer calories, less salt, and has a natural mineral content of calcium, potassium, and iron all in the same serving size as table syrup. Maple syrup also has only one ingredient, and we all can pronounce it…Maple Syrup. There was a study done with Maple Syrup (found here) that revealed that Maple Syrup also has an anti-inflammatory property caused by a molecule called quebecol. I’m not going to list all the ingredients in table syrup because I have a word limit I am trying to stick to. But, when I see Corn Syrup and High Fructose Corn Syrup listed as the first two ingredients on a label, my brain just shuts down anyway. (photo credit: left - Authors Label; right The Quaker Oats Co, 2004)

Taking a gander at the ingredient labels on store-bought syrup and comparing it to maple syrup, it is quite clear who the winner is for the "Healthy Choice Award". Maple syrup contains fewer calories, less salt, and has a natural mineral content of calcium, potassium, and iron all in the same serving size as table syrup. Maple syrup also has only one ingredient, and we all can pronounce it…Maple Syrup. There was a study done with Maple Syrup (found here) that revealed that Maple Syrup also has an anti-inflammatory property caused by a molecule called quebecol. I’m not going to list all the ingredients in table syrup because I have a word limit I am trying to stick to. But, when I see Corn Syrup and High Fructose Corn Syrup listed as the first two ingredients on a label, my brain just shuts down anyway. (photo credit: left - Authors Label; right The Quaker Oats Co, 2004)

5. There are things to consider before and while tapping a maple tree.

During a season one taphole can average as much as 40-80 gallons of sap. Of course, these amounts are determinate by the size of the tree, quality of the taphole, weather, the time of day, and location. Trees under 10 inches in diameter are usually not tapped, and trees 10-20 inches only receive one tap. A second tap can be introduced on trees 20-25 inches in diameter, and trees over 25 inches can receive three taps. No more than three taps should be placed on any tree. We use 5/16 size taps and drill about 1 inch to 1 ½ inch into the tree depending on the size of the tree. A tap hole should be placed 4 feet or so from the ground and at least 12 inches below or above a previous taphole and no less than 6 inches beside an existing taphole. There is no evidence that proper tapping of a maple tree harms the tree in any way. There are records of 300-year-old maple trees that have healed tapholes present in their heartwood.

6. The production of maple syrup is farming.

As a sugarmaker, we spend plenty of time in the woods year- round. Our season starts shortly after the previous season ends. There is plenty of equipment to clean, maintenance to perform, taps to pull and clean, and branch lines and mainlines to clean. When a storm or strong wind barrels through the area, there is usually a down tree or two that must be removed from branch lines and pathways. Sound practice of forest management is a must so the canopy can stay open and give the trees plenty of sun to reenergize, grow and be strong to provide plenty of sap for the next season. Some evaporators use wood to create the heat necessary to boil the sap, and others use gas or fuel oil to fire the evaporator. If a wood-fired evaporator is used for syrup production, then collecting firewood is necessary. We collect the wood we obtain from our forest management plan that we follow for our sugarbush. We start our forest management plan in the late spring and continue until the snow flies in the winter. The amount of wood that is necessary for a season depends on the efficiency of the sugarmaker's equipment. However, a rough estimate is that it will take about a full-face cord of seasoned hardwood to produce 20-25 gallons of finished syrup. One of the cool things about farming is you get to operate fun equipment like tractors, side-by-sides, and ATV’s…you know, every job must have its perks!

round. Our season starts shortly after the previous season ends. There is plenty of equipment to clean, maintenance to perform, taps to pull and clean, and branch lines and mainlines to clean. When a storm or strong wind barrels through the area, there is usually a down tree or two that must be removed from branch lines and pathways. Sound practice of forest management is a must so the canopy can stay open and give the trees plenty of sun to reenergize, grow and be strong to provide plenty of sap for the next season. Some evaporators use wood to create the heat necessary to boil the sap, and others use gas or fuel oil to fire the evaporator. If a wood-fired evaporator is used for syrup production, then collecting firewood is necessary. We collect the wood we obtain from our forest management plan that we follow for our sugarbush. We start our forest management plan in the late spring and continue until the snow flies in the winter. The amount of wood that is necessary for a season depends on the efficiency of the sugarmaker's equipment. However, a rough estimate is that it will take about a full-face cord of seasoned hardwood to produce 20-25 gallons of finished syrup. One of the cool things about farming is you get to operate fun equipment like tractors, side-by-sides, and ATV’s…you know, every job must have its perks!

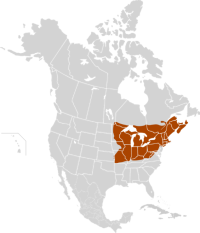

7. Eastern North America is the only area in the world that produces maple syrup.

In the United States over 13 million taps produced 4 million gallons of maple syrup in 2019, and…cough!…cough!…Vermont produced over half that amount. To produce that much syrup would require reducing 200 million gallons of raw tree sap! Our great state of Michigan produced close to 200,000 gallons in 2019, and that number is expected to rise with the cost of equipment starting to become more reasonable for more producers to enter the market. (source) The amount of syrup made in the United States would fill a swimming pool that is approximately 1000 feet long by 200 feet wide and is 10 feet deep! That’s a lot of syrup!

8. Maple syrup is a multi-functional food source.

Maple Syrup and Maple Sugar can be used in anything that you can imagine needing sweetening. Maple sugar can be used for an exact replacement for table sugar in any recipe one-for-one. Maple syrup can be used as a topping for ice cream, pancakes, and waffles. It can be made into jelly and used on toast and peanut butter and jelly sandwiches. Maple syrup can be used to sweeten baked beans, bar-b-que sauces, and well, any sauce for that matter. One of my favorites is to use a couple of tablespoons of maple syrup and add it to some ice water. This is a very refreshing sweet drink that is energizing after a scorching day of sugar farming. Have some fun experimenting with maple syrup and sugar in some of your favorite recipes.

In my opinion, the best place to obtain maple syrup is to get it directly from the source, your local sugar farmer. Not only will there be pure maple syrup packaged in sizes from gallons down to half pints, but there will also likely be candy, granulated sugar, maple cream, and many other healthy snacks and foods made with pure maple syrup that are likely not found in stores. The best way to go about that is to take a hike, bike, or cruise over to your local farmer’s market and chat with the maple syrup vendors. There is usually one or two at every market and they are always willing to chat about maple syrup production with their customers. A farmer’s market is the best way to get to know your local farmers and to support small businesses and families. Go get your market basket and support your farmers!

For more information on where you can get locally made maple syrup at the local farmer's markets in Leelanau, visit https://leelanaufarmersmarkets.com/markets/.